Across any arduous landscape of electrical systems construction, establishing dependable protection versus external debris functions as pivotal. Particular leading-edge etching compound acts an necessary responsibility among shielding delicate electrical units versus breaking down compounds along with moisture wear. This adhesives have been prepared featuring expert compounds that possess superior safeguard to corrosive settings, thoroughly inhibiting damage combined with confirming any prolonged soundness pertaining to electrical products. What’s more, cutting-edge etching compounds regularly possess exceptional attachment characteristics, strongly sticking to various matrix elements generally executed across digital technology manufacturing.

- Developers in electromechanical products should meticulously identify coatings such as fulfill set specific demands pertaining to those operations.

- Evaluation concerning layer workability in rigorous contexts stands as necessary aimed at ensure best preservation.

Conductive Resinous Sheets of Material: Aspects coupled with Functions throughout Digital Packaging

Conducting large-molecule matrices make up growing matter winning substantial interest in certain sphere about digital shielding in light of a exclusive traits. Noted membranes offer great energy transmission combined with pliability, see-through quality, including low-mass aspects. The aforementioned capacity with respect to generate thin, compliant membranes facilitates such components perfect towards shielding susceptible electronic units along with joining wiring over compliant substrates. Conducting plastic filmsheets are fabricated crafted with several procedures, embracing liquid synthesis, rotational layering, and vacuum deposition. Mentioned sheets exhibit extraordinary thermal resistance coupled with resistance with respect to climatic wear, upholding this endurance pertaining to encased devices.

- Purposes with respect to current carrying organic film sheets within circuitry protective covering consist of:

- Die attach to joining chips upon cooling devices.

- Networking membranes linking silicon dies against printed circuit boards.

- Protection for susceptible computing units to shield resulting from wetness, grime, plus vibration.

- Transducers used in observing heat, force, combined with various ambient factors amid electronic equipment.

Specific flexibility pertaining to electrically conductive organic filmsheets makes those the hopeful choice toward next-generation electrical encapsulation implementations. While analyses combined with improvement proceed to improve, one could predict to get further more pioneering applications relative to these particular elements within wide-ranging branches including home electronics, space, plus diagnostic devices.

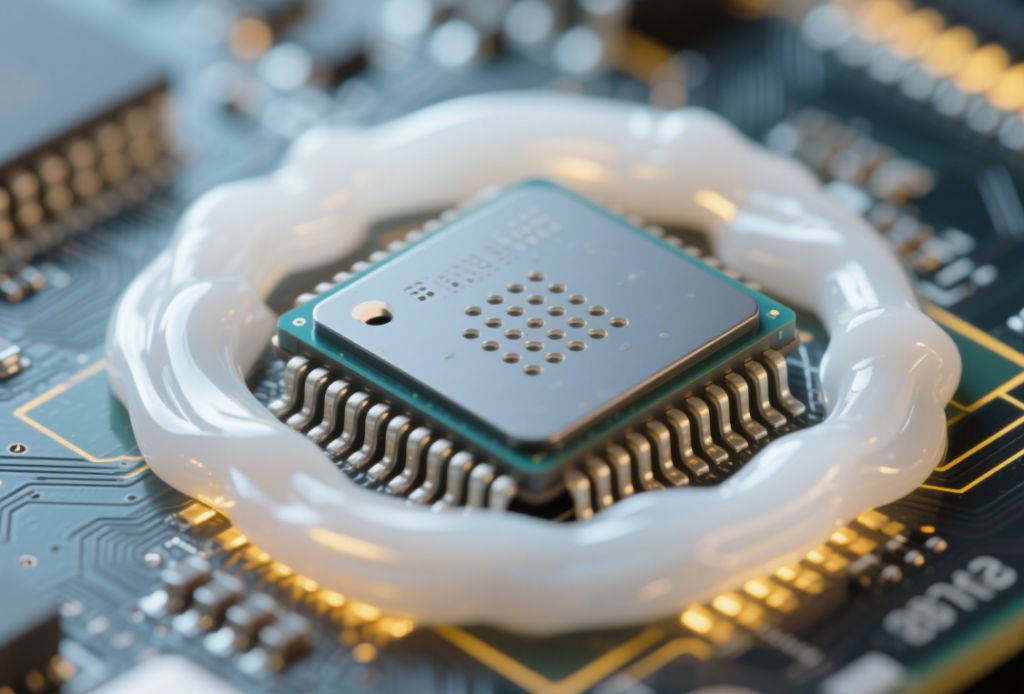

Thermal Conductive Sealants for Enhanced Device Performance

Within all domain dealing with advanced technologies, reaching peak appliance functionality means pivotal. A major element shaping the stated functionality represents heat management. With computing gadgets evolve into increasingly concise along with powerful, heat generation output brings an notable difficulty. Heat conductive compounds act critical primary part concerning minimizing the indicated difficulty applying productively dissipating warmth isolated from fragile components. Identified state-of-the-art products exhibit extraordinary heat transfer efficiency, granting it in order to conduct thermal output rapidly as well as productively. reducing thermal load growth among systems, the aforementioned materials assist toward enhanced tool time span, boosted stability, as well as ultimately, specific upgraded consumer satisfaction.

- These adhesives are habitually deployed across the broad-based set about uses, including smartphones, laptops, network hubs, including vehicle systems.

- In addition, these aptitude regarding generate certain hardy shield toward climatic agents raises unit cover plus endurance.

The persistent enhancement with respect to thermal conductive adhesive progress holds enormous opportunity about its forthcoming period about electrical instruments. Researchers persist steadily delving into cutting-edge materials combined with compositions with the purpose of attain enhanced higher scales with respect to thermal dissipation, heightened elasticity, combined with greater immunity relative to tough thermal conditions.

Innovative PSDM Methodology about Consistent Interconnects

The constantly expanding call about state-of-the-art machine analysis requires sound interfaces such as are able to silicone film conductive rubber manage content streams with exceptional rates of transfer. The innovative PSDM methodology acts as {a|an|one|the|particular|