Initiating introduction relating to drop-on-demand printing, recognized for its adjustability in developing sharp graphics on multiple bases, frequently facing barriers when executed on spherical carriers. The fundamental trait of these areas, notorious for their uneven structures, elicits serious obstacles for the correct and balanced positioning of ink droplets. Traditional inkjet printing systems, frequently tailored for horizontal planes, frequently fail to keep proper management over ink placement on curved areas, giving rise to aberrations in the graphics.

- Furthermore, the adhesive properties of the ink can be undermined by the shape of the surface, resulting in ink bleeding. This can greatly affect the clarity of the printed output.

- Combined with, the material bounds imposed by curved surfaces can constrain the movement of the printhead, further adding to the printing process.

To address these complexities, researchers and engineers have formulated innovative solutions that aim to boost the inkjet printing process on curved surfaces. These initiatives often involve adaptations to the printhead design, ink formulation, and printing process parameters.

Advanced Small Font Digital Inkjet Technology

Ultra-fine symbol jetting technology enables the precise deposition of ink onto substrates at a minuscule scale. The method versatile techniques leverage specialized printheads capable of delivering incredibly fine droplets, allowing for the creation of legible and dense text at resolutions ranging from over 1000 DPI. The application of this technology spans a wide variety of industries, including electronics manufacturing, pharmaceuticals, and label production.

- Examples of high-resolution small character inkjet printing encompass the production of tiny circuit boards, printed sensors, microfluidic devices, and highly detailed labels.

- The accuracy offered by this technology is crucial for achieving optimal performance in these applications.

- As well, advancements in ink formulations ceaselessly expand the capabilities of inkjet printing, enabling the delivery of a greater variety of materials, including conductive inks, biocompatible polymers, and even substances at the nanoscale.

Compact Handheld Inkjet Devices: Progress in Mobile Labeling

The accelerated development of compact designs has led to significant strides in the field of handheld inkjet printers. These compact and versatile devices are revolutionizing portable marking applications across various industries.

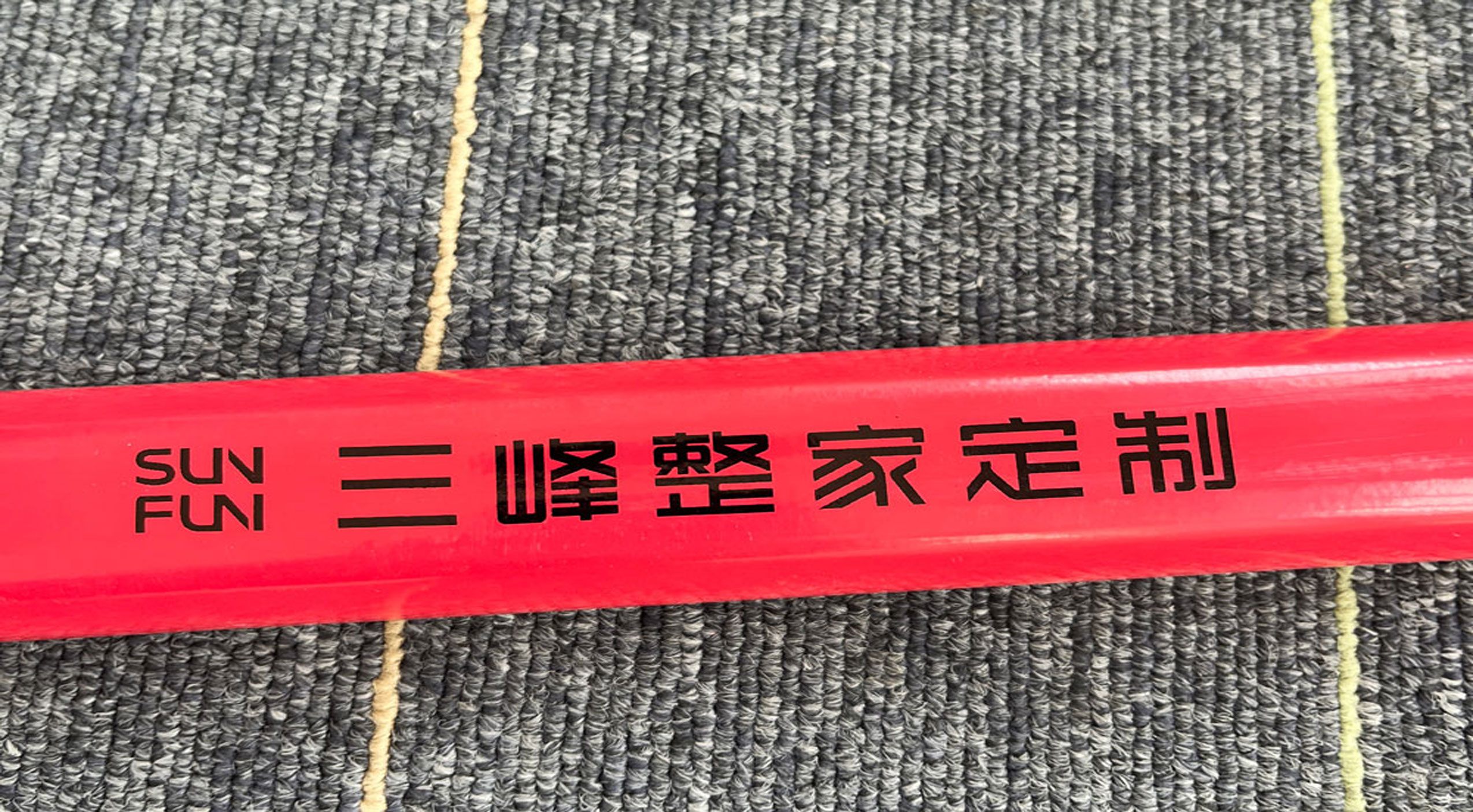

Boasting condensed form and featherweight construction, handheld inkjet printers offer exceptional portability, allowing users to print directly on a considerable set of bases, including plastic, metal, glass, and fabric. The implementation of advanced ink technologies has further enhanced the capabilities of these printers, enabling them to produce high-resolution, durable prints that withstand demanding environmental conditions.

What's more, handheld inkjet printers are becoming increasingly easy-to-operate, with straightforward interfaces and easy-to-use software solutions. This makes them an ideal choice for both professionals and individuals seeking a reliable solution for on-demand marking needs.

As developments unfold, we can expect even more trendsetting advancements in handheld inkjet printers, pushing the boundaries of portable marking applications.

Self-Regulating Inkjet Machines: Industrial Productivity Solutions

Amidst innovative manufacturing settings, efficiency reigns supreme. Digital inkjet printing systems have emerged as a revolutionary technology, enabling businesses to achieve unprecedented levels of automation and productivity. These cutting-edge systems leverage precise ink deposition techniques to produce high-quality prints on a wide range of materials, from textiles and electronics to packaging and labels. By streamlining production processes and minimizing manual intervention, machine-controlled inkjet printing empowers manufacturers to optimize their output, reduce costs, and enhance overall operational efficiency.

- Refined workflow processes

- Decreased labor costs

- Enhanced product quality

Adaptable Surface Inkjet Methods: Critical Review

Ink emission processes serve expandable applications for the fabrication of electronic devices and other functional materials due to its scalability. This review article provides a comprehensive overview of recent advances in inkjet printing on elastic substrates. We examine various aspects, including foundation elements, ink formulation, printing conditions, and emerging operations. The focus is on the challenges associated with inkjet printing on flexible substrates and the techniques employed to overcome these limitations. The article also highlights the possibilities of this technology for fabricating next-generation systems.

- The review provides a comprehensive assessment of recent advancements in inkjet printing on flexible substrates.

- We delve into the specifications of various compliant substrates and their influence on the printing process.

- Illustrative cases are presented to demonstrate the deployments of inkjet-printed flexible electronics in diverse fields.

Additive Manufacturing of Curved Surfaces via Direct Inkjet Printing

The landscape of growth fabrication routinely enhances, pushing the boundaries of what's workable with innovative techniques. Among these advancements, direct inkjet printing (DIP) has emerged as a versatile tool for creating complex three-dimensional objects. Traditionally, DIP has been generally associated with flat substrates. However, recent research studies the exciting frontier of printing on curved surfaces, opening up extensive range of applications.

Fabrication on curved objects presents unique challenges due to its intricate form of the substrate. Factors such as surface tension, material flow, and adhesion need to be carefully controlled to ensure a high-quality print. Researchers are developing various strategies to counter these challenges, including adaptive printing heads, novel printing materials, and sophisticated control algorithms.

- One promising direction involves the implementation of soft robotics principles to create flexible printing heads that can conform to the curved surface. This approach allows for a more highly-controlled deposition of material, diminishing defects and enhancing the quality of the printed object.

- Besides, researchers are investigating the use of digital drafting programs to optimize the printing process for curved objects. By simulating the printing process, designers can spot possible problems and make necessary adjustments to ensure a successful print.

Projected roles of direct inkjet printing on curved objects are vast and include fields such as aerospace, automotive, biomedical engineering, and consumer materials. From high-performance aircraft components to personalized medical implants and intricate designs, the possibilities are truly limitless.

Flexible Inkjet Printing for Unique Geometry: Design Personalization

Responsive droplet emission method is developing as a potent solution for fabricating intricate shapes and patterns. By dynamically adjusting the print parameters, such as droplet size, spacing, and ejection frequency, this technology enables the creation of complex geometries with high precision and resolution. The ability to tailor print patterns to specific criteria opens up a wide range of applications in diverse fields, including electronics, biomedical engineering, and manufacturing.

One key advantage of adaptive inkjet printing lies in its adjustability. Specialists can design intricate patterns that precisely match the desired geometry of the final product. This eliminates the need for costly and time-consuming tooling, making it an ideal solution for prototyping and low-volume production. Furthermore, the non-contact nature of inkjet printing allows for the fabrication of delicate structures without mechanical stress or deformation.

Adaptive inkjet printing also exhibits peerless resolution capabilities, enabling the creation of fine details and intricate patterns. This makes it suitable for applications such as printed electronics, where precise placement of conductive traces is essential. By controlling the orientation of droplets, complex circuitry can be fabricated with high accuracy and reproducibility.

Carryable Droplet Printers: Useful Gadgets for Prompt Branding

Portable jet printers rise in adoption as a secure solution for businesses desiring on-demand marking and labeling. These small devices offer a amplified range of applications, from branding product information and tags to developing custom graphics and emblems. With their user-friendly interface and swift printing speeds, handheld inkjet printers provide a versatile solution for countless industries.

- Sectors that benefit from handheld inkjet printers consist of:

- Manufacturing

- Distribution

- Biomedical

- Telecommunications

Acute Micro-Text Inkjet Techniques for Fine Resolution

Exact miniature font jet techniques become pivotal for realizing microscopic detail in distinct practices. This progressive printing approach adopts tiny ink droplets, precisely sprayed onto bases at a tiny level. This manifests intricate structures with unmatched accuracy and sharpness.

- Featuring high-density circuit boards to nanoscale sensors, precision small character inkjet printing is transforming the manufacturing of petite components.

- In addition, its ability to dispense a wide array of materials, including inks, polymers, and even biomolecules, augments its applications.

Thus, precision small character inkjet printing is rising as a dominant tool for scientists in legioned fields, supporting advancements in nanotechnology, and beyond.

Upcoming Directions in Automated Inkjet Fabrication

The arena of smart printing observes rapid development, with inkjet technology at the forefront. Tendencies indicate a future where inkjet printing becomes increasingly complex, capable of producing top-tier outputs on a wide range of substrates.

- Anticipate advancements in ink formulas that enable multi-color prints with enhanced attributes.

- Incorporation with cognitive algorithms will accelerate printing processes, resulting in strengthened operation.

- Successive layering using inkjet technology is gaining drive, opening up breakthrough potentials in branches such as transportation.

Besides, the emergence of malleable electronics and dynamic composites will stimulate further innovation in automatic inkjet printing, leading to a landscape where printing progresses into an essential instrument for industrial production.

Curved Surfaces: A New Frontier in Inkjet

The scope of micro-printing is fast innovating, pushing the boundaries of what's possible with this versatile technology. Previously, ink emission prioritized smooth contours, but now researchers are exploring innovative materials and techniques for application on undulated profiles. This presents a unique set of challenges and opportunities in the field of materials science.

One crucial aspect is the selection of print media that can remain stable to curved surfaces, withstanding the inherent stresses and strains caused by the molding. As well, materials must exhibit suitable rheology to ensure precise deposition and fine resolution on these complex geometries.

- Enhancements in synthetic compounds play a crucial role in creating inks and substrates that can conform to curves.

- Ultrafine particles, demonstrating exceptional features, open prospects for elevated jet application on contoured bases.

The prospective implementations of inkjet printing on curved surfaces are vast and varied, ranging from customized medical implants to automotive components. As research in this area continues to expand, we can expect to see even more innovative applications emerge, further blurring the lines between traditional printing methods and cutting-edge material science.

automatic inkjet printer